SOLSPOT 5000 STEEL + KIT STUDDER

The SOLSPOT 5000 STEEL is a specialized machine for bodywork repair through spot welding and localized heating. Designed for straightening metal sheets in cars and trucks, it offers manual and automatic operating modes, allowing precise work on steels and alloys without deformation. It features five pre-installed welding programs and an exclusive function that allows operation with a half welding cycle, ideal for thin sheets. It comes equipped with accessories such as a welding gun, ground cable, and brass slide hammer.

Main Features:

✓ Designed for automotive and truck bodywork, compatible with all types of steel and their alloys.

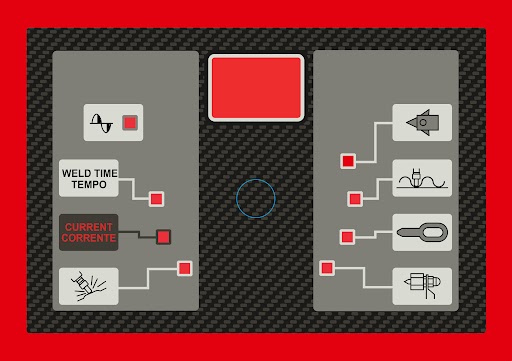

✓ Automatic and manual modes, selectable from the front control panel with parameter display.

✓ Half welding cycle capability, unique in the market, to prevent deformation on thin sheets.

✓ Carbon electrode for localized heating applications, ideal for thermal dent removal processes.

✓ 5 pre-installed welding programs, configurable according to the operator’s needs.

✓ Multifunction gun and complete wiring included, ready for use from the very first moment.

✓ Integrated thermal protection in both the transformer and the gun for enhanced safety and durability.

✓ Intuitive control panel, featuring current, welding time, and cycle status indicators.

✓ Recommended for industrial environments, suitable for installation on 230V networks with TT or TN grounding systems.

✓ Compatible with optional transport cart Ref. 10408 for greater mobility in workshops.

| General | |

|---|---|

| Intensity MAX. | 1800A |

| Tech | |

| Power absorbed 50% | 2,0Kva |

| Operating Voltage (Vmp) | 8V |

| Welding Time | 0,5 - 99 |

| Electric | |

| Supply Voltage | 230V-1ph |

| Fuse | 8A |

| Maximum absorbed power | 12Kva |

| Structural | |

| Weight | 16 kg |