SOLSPOT 9000+SPOT GUN+KIT STUDDER

The SOLSPOT 9000 by Solter is a spot welding machine with a pneumatic clamp for sheets up to 3+3 mm, specially designed for bodywork repairs. It incorporates synchronous digital control with dual program, ensuring precise welds even on stainless steel and galvanized sheets. Its versatility allows simultaneous use of the pneumatic clamp and the Spotter dent puller, optimizing working time. With continuous adjustment of current and time, as well as compensation functions for oxidized sheets, the SOLSPOT 9000 combines power, reliability, and ergonomics, making it the ideal tool for both professional workshops and specialists in car and truck repair.

Main Features:

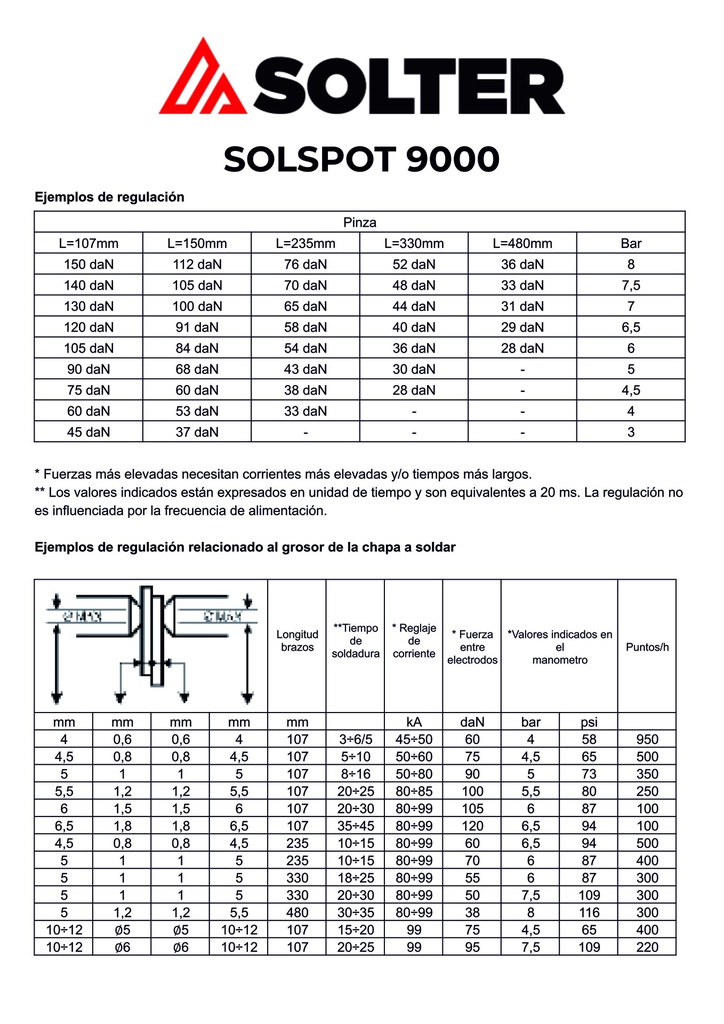

✓ Spot welding of sheets and chassis up to 3.0 + 3.0 mm in carbon steel, stainless steel, and their alloys.

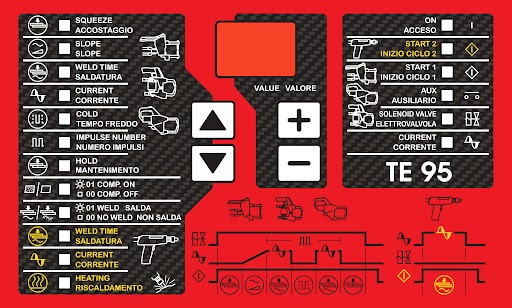

✓ TE95 digital control with dual program, allowing differentiated cycles for clamp and dent puller.

✓ Compensation and pulsing function, ideal for oxidized or galvanized sheets.

✓ Simultaneous connection of pneumatic clamp and Spotter gun, with automatic program recovery.

✓ Continuous adjustment of current (1–99%) and welding time (1–99 cycles).

✓ Lightweight pneumatic clamp with interchangeable arms and water-cooled electrodes.

✓ Includes Studder Kit for dent pulling with gun, cables, and complete accessories.

✓ Trolley with height-adjustable wheels and integrated air pressure reducer.

✓ Compatible with optional pneumatic cooling unit (Ref. 10369) for high-demand applications.

✓ Rated power of 10 kVA and welding capacity with a maximum current of 6.4 kA, ensuring strong and durable joints.

| General | |

|---|---|

| Intensity MAX. | 8000A |

| Tech | |

| Potencia absorvida 50% | 10Kva |

| Voltaje de servicio (Vmp) | 8V |

| Tiempo de soldadura | 1-99 |

| Electric | |

| Supply Voltage | 400V - 1ph |

| Fuse | 25A |

| Absorved power max. | 50Kva |

| Structural | |

| Weight | 105 kg |